Are you tired of constantly reprinting labels due to smudging, fading, or tearing?

Many businesses face labelling challenges when using regular printers that aren’t designed for label printing. However, the good news is that there is a solution – investing in a dedicated printer for labels.

In this blog post, we’ll walk you through the reasons why your business needs a dedicated printer for labels, the benefits of using one, the types of label makers available, and the factors to consider when choosing one.

By the end of this post, you’ll understand how a dedicated label printer can streamline your labelling process, save you time and money, and ensure that your labels are of the highest quality. So, let’s dive in!

Reasons to Avoid Using Regular Printers for Label Printing?

Regular printers simply aren’t designed for printing labels. Here are some common labelling challenges businesses face when using regular printers:

1) Difficulty in printing high-quality labels

Regular printers are not designed to handle the specific requirements of label printing, such as precise placement, high-resolution graphics, and durable materials.

This can result in labels that are smudged, faded, or difficult to read, which can negatively impact the product’s image and brand.

2) The possibility of using wrong label materials

Another challenge is the possibility of using the wrong label materials. Regular printers may not be compatible with all types of label materials, and using the wrong materials can result in poor-quality labels that do not adhere properly, tear easily, or fade quickly.

This can lead to wasted time and resources on printing and re-printing labels, which can be frustrating and costly for businesses.

3) Wasted time and resources on printing and re-printing labels

Moreover, the process of printing and re-printing labels using regular printers can also be time-consuming and inefficient.

In addition to the challenges mentioned above, regular printers may also require frequent ink or toner changes, paper jams, and other technical issues, which can further delay the labelling process.

Benefits of Using a Dedicated Printer for Labels

Investing in a dedicated printer for labels can provide businesses with a range of benefits, including:

1) Higher-quality printing results:

Dedicated label printers are designed to handle the specific requirements of label printing, such as high-resolution graphics, precise placement, and durable materials.

As a result, businesses can expect high-quality printing results with clear, legible labels that are easy to read and identify.

2) More durable and long-lasting labels:

Dedicated label printers use specialized materials and inks that are designed to withstand harsh environments, such as exposure to moisture, heat, and sunlight.

This ensures that labels are more durable and long-lasting, which can improve the product’s image and brand and reduce the need for frequent label replacements.

3) More efficient label printing process:

Dedicated label printers are specifically designed for label printing, which means they are more efficient and can handle high-volume printing without delays or technical issues.

This can streamline the labelling process, save time, and increase overall productivity.

4) Cost savings in the long run:

While the upfront cost of a dedicated label printer may be higher than a regular printer, the cost savings, in the long run, can be significant.

With higher quality and more durable labels, businesses can reduce the need for frequent label replacements, which can save money on materials and printing costs in the long term.

Types of Label Printers

There are several types of label printers available on the market, each with its own advantages and disadvantages. The three main types of label printers based on size are:

1) Desktop printers:

These are the most common type of label printers and are ideal for small businesses or home offices. They are compact, affordable, and easy to use, making them a popular choice for businesses that do not have high-volume printing needs.

Desktop printers are suitable for printing basic labels, such as shipping labels, address labels, and barcode labels.

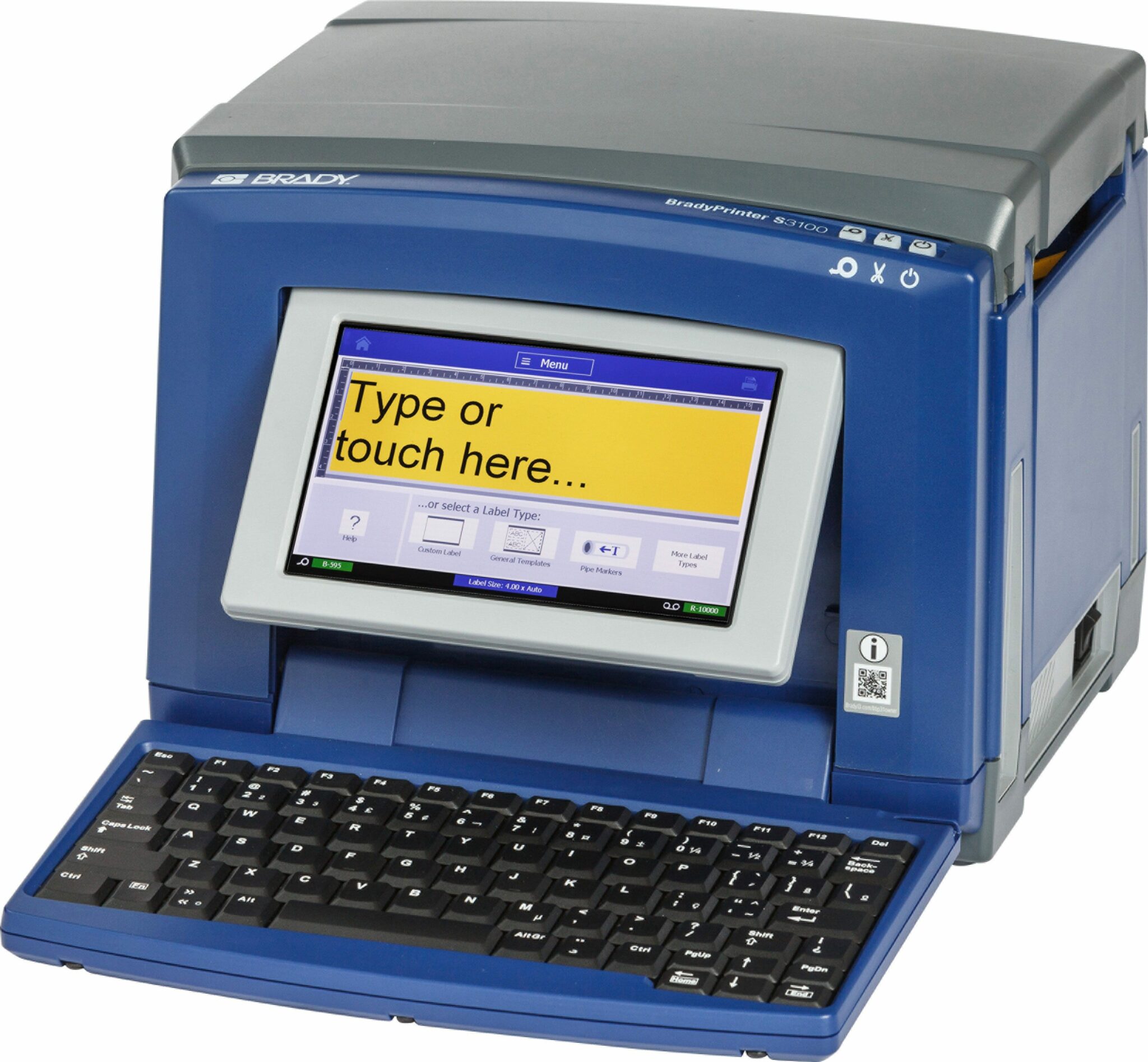

2) Industrial printers:

These are heavy-duty label printers designed for high-volume label printing in industrial environments.

They are larger, more robust, and more expensive than desktop printers, but they can handle more complex label printing requirements, such as printing on specialized label materials, producing high-resolution graphics, and handling large label rolls.

Industrial printers are suitable for businesses that require high-quality labels for products, packaging, and shipping.

3) Mobile printers:

These are portable label printers designed for on-the-go label printing needs. They are compact, lightweight, and can be easily carried around, making them ideal for businesses that require label printing in the field or on the shop floor.

Mobile printers are suitable for printing labels on demand, such as asset labels, inspection labels, and maintenance labels.

Other printers, categorised based on functionality, include:

4) Thermal Printers

Thermal label printers are a type of printer that uses heat to print on specially designed thermal label paper. The paper used in thermal label printers is coated with a heat-sensitive material that darkens when heat is applied. When the printer heats up specific parts of the paper, it creates an image or text on the label. There are two main types of thermal printers which are:

a) Direct Thermal Printers:

Direct thermal printers use heat to create an image directly on the label paper.

These printers have a thermal print head that applies heat to the paper, which causes a chemical reaction in the heat-sensitive coating. This reaction causes the paper to darken in the areas where the heat is applied, creating an image or text.

Direct thermal printers do not require ink, toner, or ribbon, which makes them simple and cost-effective to use. However, the labels produced by direct thermal printers can be sensitive to heat, light, and other environmental factors, which can cause the label to fade or darken over time. This limits the lifespan of the labels and makes them less suitable for long-term labelling applications.

Direct thermal printers are commonly used for short-term labeling applications, such as shipping labels, barcode labels, and receipts. They are also used in healthcare settings to print labels for patient information, medication labels, and wristbands. Direct thermal printers are typically faster than thermal transfer printers and produce higher-quality text and images.

They are also more affordable to operate since they do not require consumables such as ink or toner.

b) Thermal Transfer Label Printers

Thermal transfer printers use a heat-sensitive ribbon to transfer ink onto the thermal label paper. These printers have a thermal print head that applies heat to the ribbon, which causes the ink to melt and transfer onto the label paper. The ribbon and label paper are fed through the printer together, and the heat-sensitive ribbon acts as a carrier for the ink.

Thermal transfer printers can use different types of ribbons, including wax, resin, or a combination of both. Wax ribbons are the most common and are used for printing on paper labels, while resin ribbons are used for printing on synthetic labels that require more durability and resistance to harsh environments.

Unlike direct thermal printers, thermal transfer printers can produce high-quality, long-lasting labels that are resistant to fading and environmental factors such as heat, light, and moisture. This makes thermal transfer labels suitable for labeling applications that are durable and long-lasting, such as product labels, asset tags, and identification badges.

Thermal transfer printers are more expensive than direct thermal printers and require the use of consumables such as ribbons and label paper. However, the flexibility and durability of the labels produced by thermal transfer printers make them a popular choice for businesses that need to print high-quality, long-lasting labels for a variety of applications.

5) Laser Printers

Laser printers are a type of printer that uses toner and heat to create an image or text on paper or other materials. While laser printers are primarily used for printing on standard paper, they can also be used for printing labels.

Laser printers for labels typically use a special type of label paper that is compatible with the high heat generated by the laser printer’s fuser unit. The fuser unit is the component of the printer that melts the toner and fuses it onto the paper or label material.

Laser printers for labels offer several advantages over other types of label printers. They can produce high-quality, detailed images and text, and can print in color or black and white. Laser printers can also handle a wide range of label sizes and materials, making them versatile and flexible for a variety of labeling applications.

However, laser printers for labels also have some drawbacks. They can be expensive to purchase and maintain, and require regular toner replacement. They may not be suitable for applications where labels need to be extremely durable or resistant to environmental factors, such as exposure to heat or moisture.

While laser printers are primarily designed for printing on standard paper, they can be used for printing labels as well. Laser printers for labels offer high-quality printing and flexibility in label size and material, but may not be the best choice for all labeling applications. It is important to carefully consider the specific labeling needs of a business or organization when choosing a label printing solution.

6) Inkjet Printers

Inkjet printers are a type of printer that uses liquid ink to create images or text on a variety of media, including label paper. Inkjet printers for labels are similar to standard inkjet printers, but they are specifically designed to handle label stock and produce high-quality, durable labels.

Inkjet printers for labels typically use dye-based or pigment-based inks. Dye-based inks produce bright and vibrant colors, but they can fade over time when exposed to light and environmental factors. Pigment-based inks, on the other hand, are more durable and resistant to fading, making them a better choice for labels that need to last for a long time.

Inkjet printers for labels offer several advantages over other types of label printers. They can produce high-quality labels with fine detail and sharp text, and they can print labels in full color. They are also relatively affordable and easy to use, and they do not require the use of consumables such as ribbons or toner.

However, inkjet printers for labels do have some limitations. They are typically slower than other types of label printers, which can be a disadvantage if you need to print a large volume of labels quickly. They also require special label stock that is designed for use with inkjet printers, and some types of label stock may not be compatible with certain inkjet printers.

Inkjet printers for labels are a good choice for businesses that need to print small to medium volumes of high-quality, full-color labels. They are commonly used for product labelling, marketing materials, and packaging labels.

Factors to Consider When Choosing a Label Printer

Choosing the right label maker for a business can be a challenging task, given the wide range of options available on the market. To help businesses make an informed decision, there are several factors to consider when choosing a label printer, including:

1) Type of labels to be printed:

To print labels, knowing the type of label needed will determine the type of label printer required. For example, businesses that need to print basic shipping or address labels can use a desktop printer, while those that require more complex labels, such as barcode labels, product labels, or chemical labels, may need an industrial printer.

2) Print volume:

The volume of labels that a business needs to print is another important factor to consider when choosing a label printer. For high-volume printing needs, an industrial printer is recommended, while for low-volume printing needs, a desktop or mobile printer may be more suitable.

3) Required printing speed:

The printing speed required by a business will depend on the printing volume and the frequency of label printing. Industrial printers are generally faster than desktop or mobile printers, making them a better choice for businesses with high-volume printing needs.

4) Cost and budget:

The cost of a label printer is an important factor to consider, as it can vary significantly depending on the type and model of the printer. Businesses should consider their budget when choosing a label printer and weigh the upfront cost against the long-term cost savings that a dedicated label printer can provide.

Conclusion

Labelling is a critical aspect of many businesses, and investing in a dedicated printer for labels can help improve the efficiency, quality, and cost-effectiveness of the labelling process. The challenges of printing high-quality labels with regular printers can lead to wasted time, resources, and money.

At Jabac, we offer a range of label printers to suit various business needs. If you’re looking for a label printer that meets your specific label printing requirements, contact us today. We’d be happy to help you find the printer that’s right for your business.

Categorised: 2023